Optimizing Operations: A Guide to Sulzer Pumps in the Paper and Pulp Industry

In the paper and pulp industry, where reliability and efficiency are paramount, using the correct pump becomes crucial. Sulzer pumps are indispensable assets in this regard. These pumps are used in various processes from pulp processing to paper production. Since 1834, Sulzer has honed its expertise in building pumping solutions for crucial and complex industries, including paper and pulp. The precision design and engineering of these pumps make them ideal for addressing the unique challenges of the paper and pulp industry. Are all Sulzer pumps suited for the said industry? If not, then which are the best ones? What makes these pumps more popular than other pumping solutions in the market? Read this post to know these answers and more.

Discovering Sulzer Pumps: Elevating Efficiency in the Paper and Pulp Industry

There are several operational challenges in the paper and pulp industry. Most regular pumps cannot handle abrasive and corrosive slurries, viscous liquids, or withstand temperature and pressure extremities. This is where Sulzer pumps stand out. Although most Sulzer pumps possess robust construction, not all are fit for the paper and pulp industry. This section offers an overview of the Ahlstrom/ Sulzer paper equipment and pump models.

- SULZER AHLSTAR APP/APT Process Pumps: These are high-performance process pumps designed for demanding applications. They are end-suction, single-stage centrifugal pumps that ensure high process reliability, efficiency, and low operational costs in the paper and pulp industry. These pumps can handle viscous liquids, fibrous slurries, clean and lightly contaminated liquids, large solids-containing liquids, gas containing liquids, and self-priming applications, and so on.

![]()

Features

- These pumps feature high-efficiency material and hydraulics options.

- They feature innovative and cost-effective shaft sealing options to facilitate reliable operations.

- These pumps feature heavy-duty bearing units with various lubrication options.

- Their modular design helps minimize the costs of spare inventories.

- Sulzer CPT ANSI Process Pumps: These pumps are employed across paper and pulp industries owing to their simplified maintenance requirements and quick adjustments. These pumps are designed to meet the mixing, pumping, and agitation challenges in the paper and pulp industry. They can be employed for chemical recovery, chemical pulp fiber lines, finishing and coating, and so on.

Features

- Sulzer CPT ANSI process pumps feature a back pull-out design that allows easy maintenance of the rotating assembly.

- They have a self-venting feature for air ventilation.

- These pumps feature heavy-walled casing that withstand corrosion and heavy wear and tear.

- These pumps feature a semi-open impeller and are fitted with Teflon impeller O-ring.

- Semi-open impellers combined with other features such as sealing versatility, bearing house adapters and bearing monitors make them user-friendly.

- These pumps are available in various materials, including ductile iron, duplex stainless steel, and so on.

- The pumps can handle solids and fibrous materials released as a byproduct of many manufacturing operations in the paper and pulp industry.

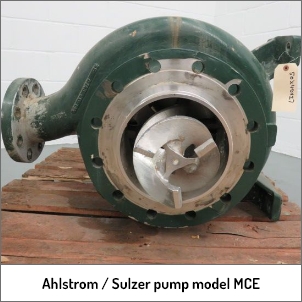

- Sulzer MCETM Pumps: Sulzer MCETM pumps were first used for chemical pulp bleaching applications in the paper and pulp industry in 1980. Over the years, the designs of these pumps have evolved in terms of increased capacity ranges, high pump heads, high pumping consistencies, and so on. The pumps are engineered based on Medium Consistency (MCTM) technology, which has been used in various process equipment and solutions from Sulzer. MCA/MCV are some popular medium-consistency fluid pumps in this category.

Features

- These pumps assure an effective hydraulic performance with reliable and sturdy mechanical designs.

- They ensure high temperature and high consistency pumping every time.

- These pumps consume less power compared to other industrial pumping solutions.

- The production rate of these pumps is 20 to 5000 ADMT/d.

- They feature pump heads up to 240 meters.

- Depending on your application requirement, these pumps can be availed with an external MDS degassing system or a built-in degassing system.

- AHLSTAR NPP/NPT Non-Clogging Process Pumps: These are non-clogging, end-suction single-stage centrifugal process pumps that are designed for pumping large solid containing liquids, large solids containing fibrous slurries, large solids and gas containing liquids and slurries, and large solids containing liquids and slurries in self-priming applications. Non-clogging design of these pumps ensure a proven solution for mixing, pumping, and agitation during cooking, screening, washing, oxygen delignification, storage and bleaching processes in paper and pulp processing units.

Features

- These pumps feature high-efficiency hydraulics options.

- They feature innovative shaft sealing options for reliable operations in challenging paper and pulp processing environments.

- These pumps feature a heavy-duty bearing unit with various lubrication options.

- Their modular design helps minimize the costs of spare inventories.

- Sulzer ZPP Double Suction Axially Split Single-Stage Centrifugal Pumps: These are single-stage centrifugal pumps designed for high-capacity applications in the paper and pulp industries. These pumps are employed for pumping clean and slightly contaminated fluids, viscous fluids, low-consistency fibrous slurries, and liquids in applications with small pressure pulsations.

Features

- These pumps feature double suction impellers with split, skewed, and staggered vanes, which assures low net positive suction head (NPSH) values and high efficiency.

- Sulzer ZPP double suction axially split single-stage centrifugal pumps feature low suction impellers that meet the stringent performance requirements in the head box applications of paper machines.

- These pumps feature renewable casing wear rings, which protect the casing from wear, assure the impeller’s smooth flow and boost efficiency.

- The wear rings are locked in the lower casing of the pumps to prevent rotation.

- The pumps can be installed horizontally or vertically, depending on the requirement.

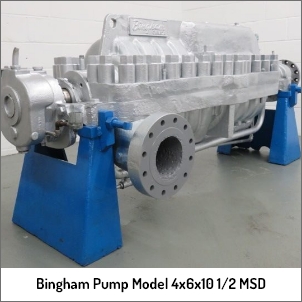

- Sulzer MSD Axially Split Multistage Pumps: MSD pumps stand out from other industrial pumps owing to their broadest range of hydraulic coverage. They are widely used in boiler feed applications.

Features

- Sulzer MSD axially split multistage pumps are available in 600#, 900#, and 1500# ratings. So, you can choose the best one for your application requirements.

- These pumps feature opposite impellers that balance axial thrust. This helps save lube system costs on most applications.

- An axially split casing on the pumps means the rotor balance isn’t disturbed upon rotor installation.

- These pumps are available in standard and high-pressure casings for various flange options.

- Sulzer Bingham MSE Multi-Stage Horizontal Centrifugal Pumps: These multi-stage horizontal centrifugal pumps are engineered for applications that demand constant pressure and flow.

If you are using any of the aforementioned Sulzer pump models, and looking for second investments or a start-up company working on a minimal budget then good quality used and surplus Ahlstrom / Sulzer paper equipment and pumps models will make the best investment. These Sulzer pump models are available at affordable prices and help you save on wait times. Sometimes, these used and surplus pumps enable you to source spare parts for obsolete models. If you have been considering used and surplus Sulzer pumps, you can contact Peak Machinery. We have consistently delivered all the pumps discussed here to our clients in the pulp and paper industry for many years. For additional information, you can contact us at Peak Machinery via phone (612) 810-1955 or email sales@peakmachinery.com to learn more about process pumps and other equipment we offer.