Krima KD-710 Dispersion System

Product ID: PC12478

- This system Includes 3 basic zones: a dewatering zone, heating zone and the disperser

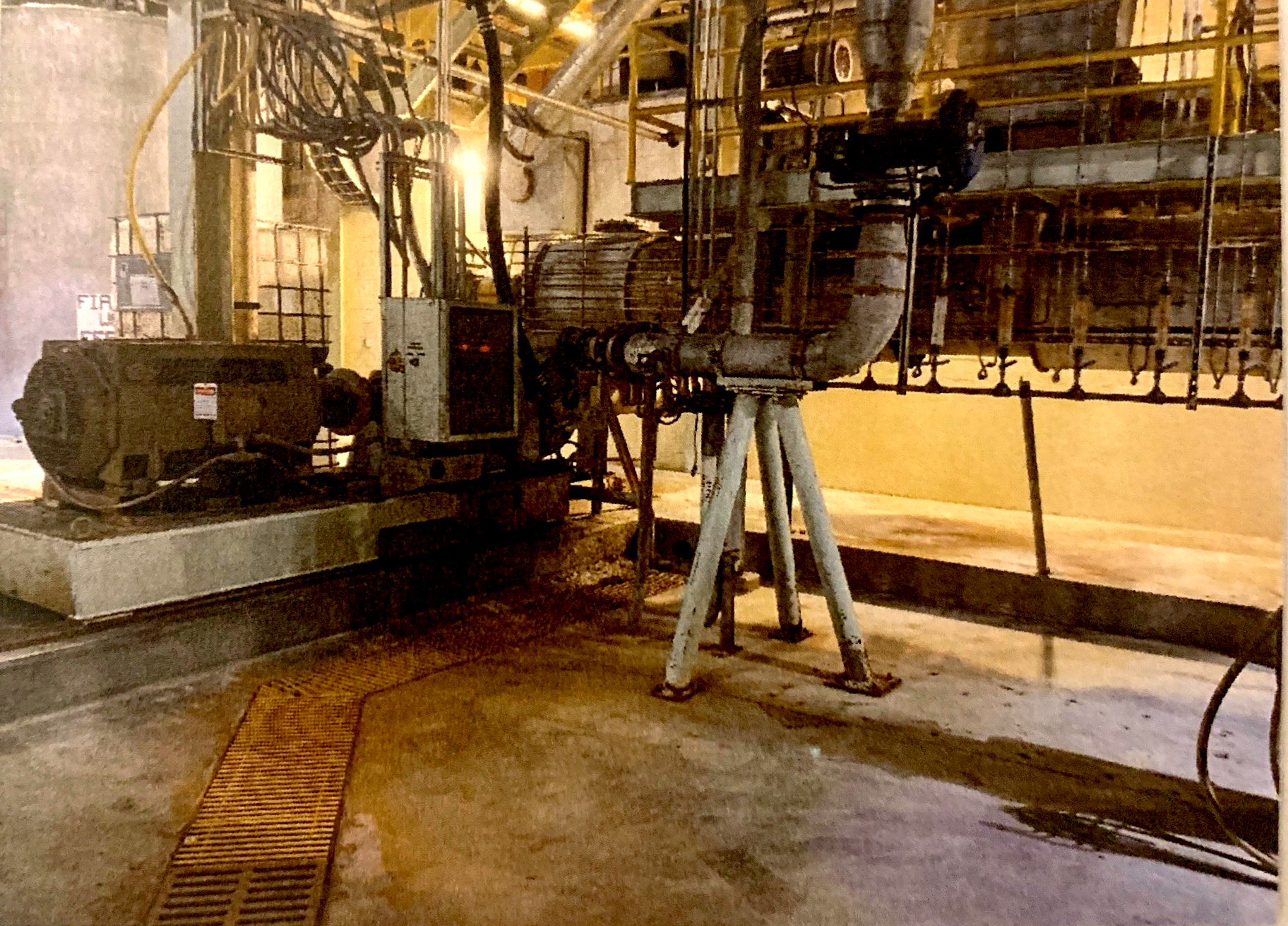

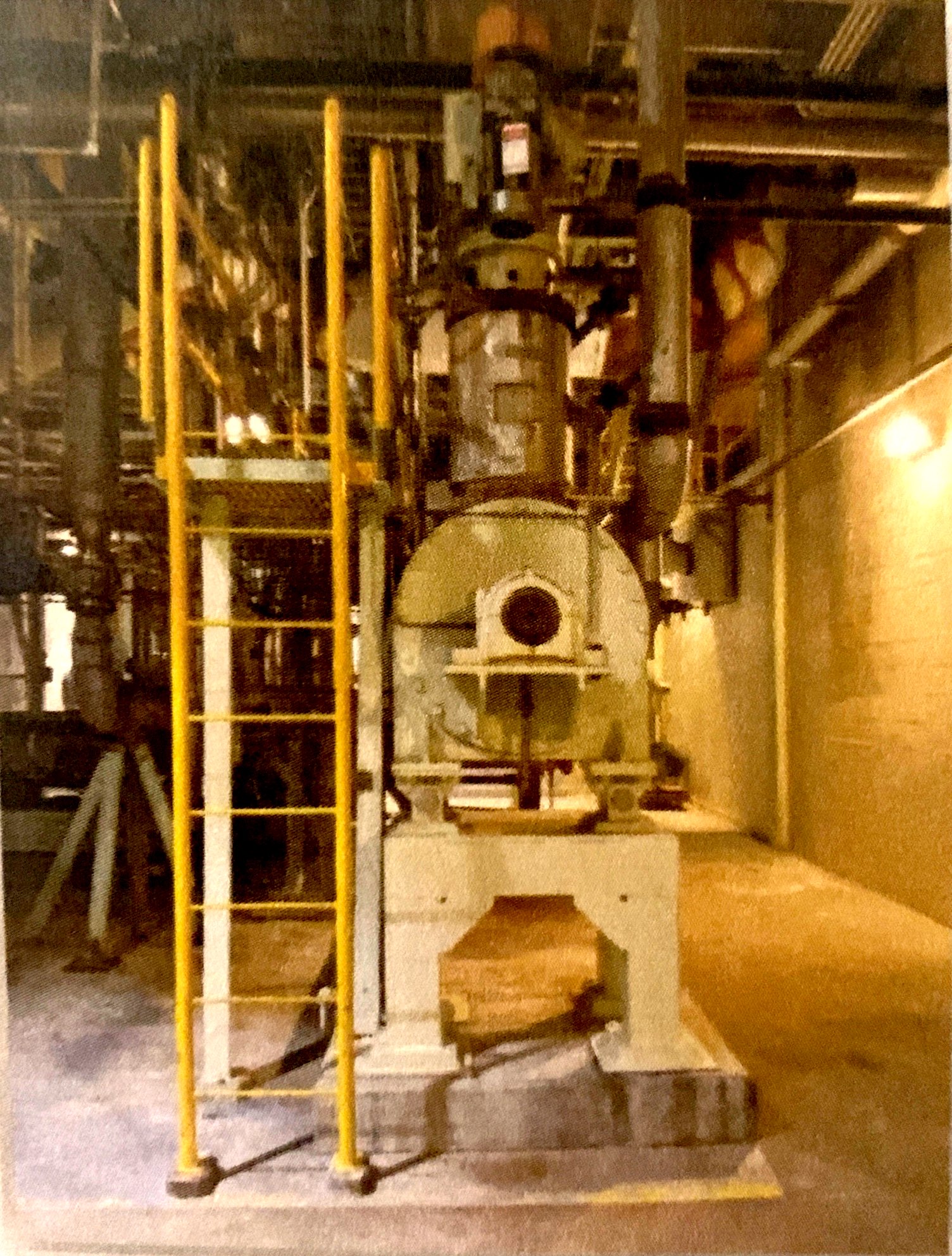

KRIMA DISPERSER TYPE KD-710

Features:

- Electro-Hydraulic disc setting (servo-controlled plate gap adjustment)

- Hydraulic System – built in to open and close disperser for maintenance and inspection, providing critical lubrication for baring assemblies, and controlling plate gap via remote operating panel. These pumps are located in the motor base along with a hydraulic reservoir. Safety switches and oil filters also located inside base.

- Headbox level detection- Ensures consistent flow of material through Disperser

- (2)Dilution Ports feeds the housing

- Disperser Motors Specs 600HP/1780RPM/4160v

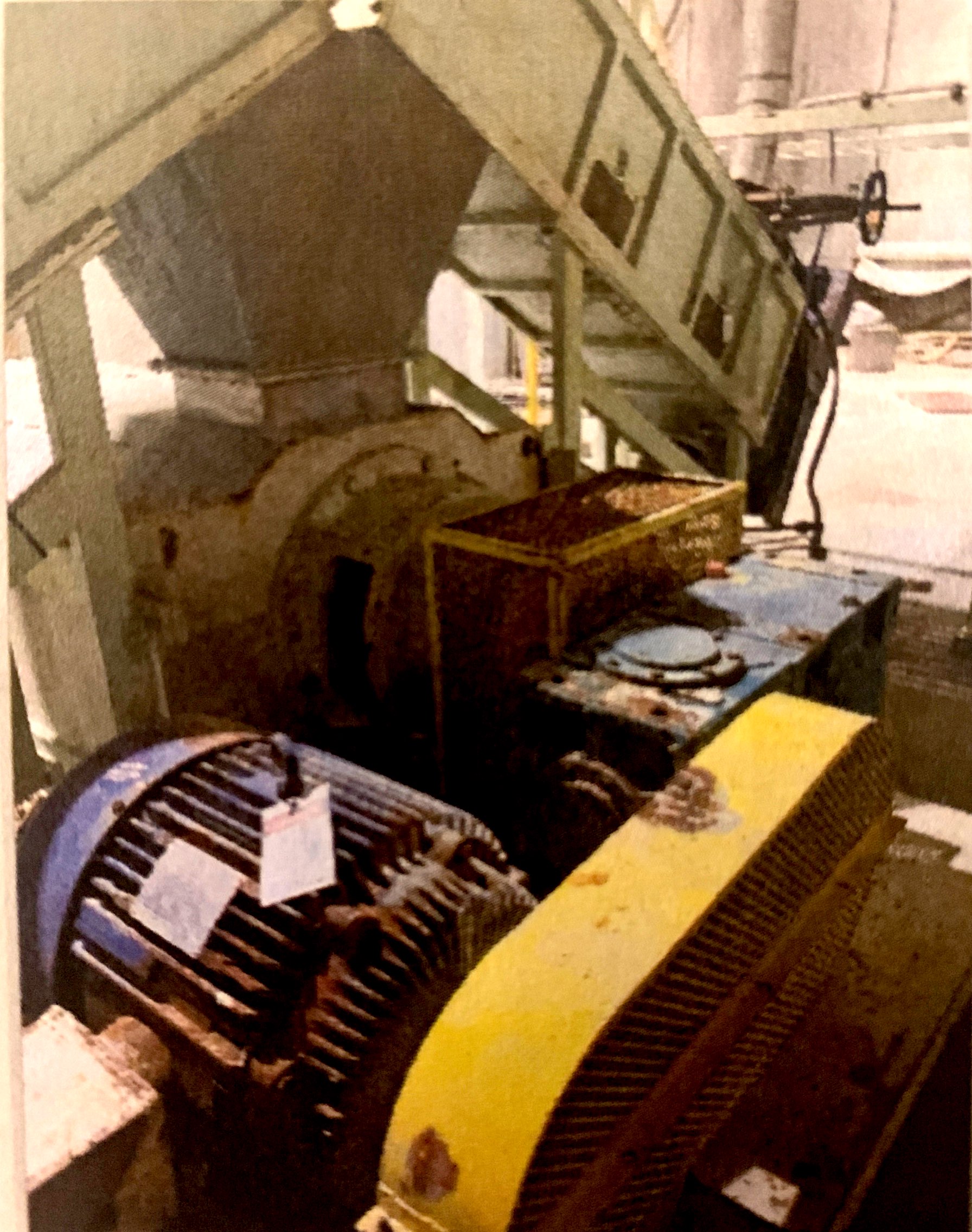

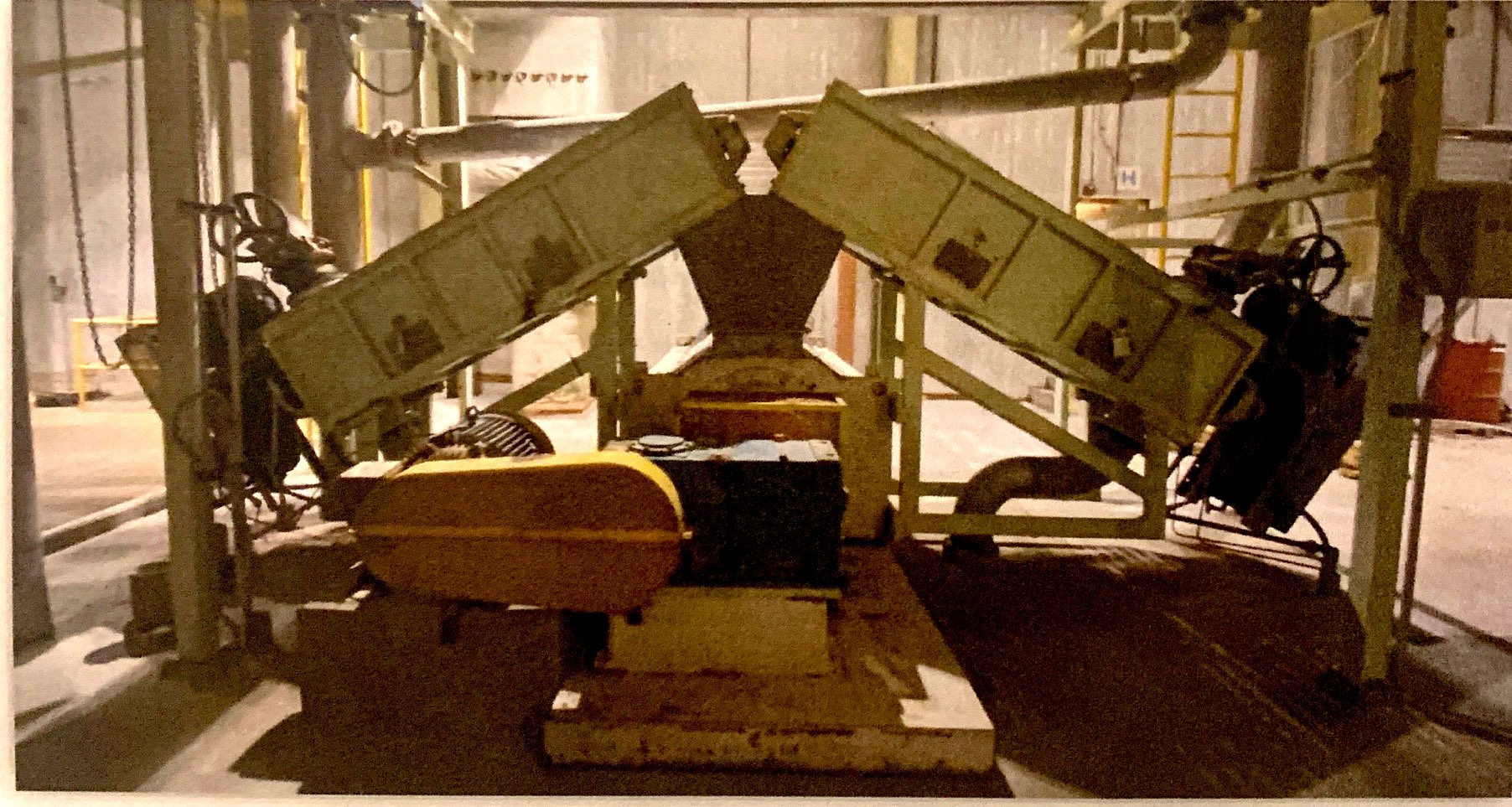

KRIMA DEWATERING INCLINED SCREW TYPE SD-2040

Qty (2) Inclined and Tapered Dewatering Screw

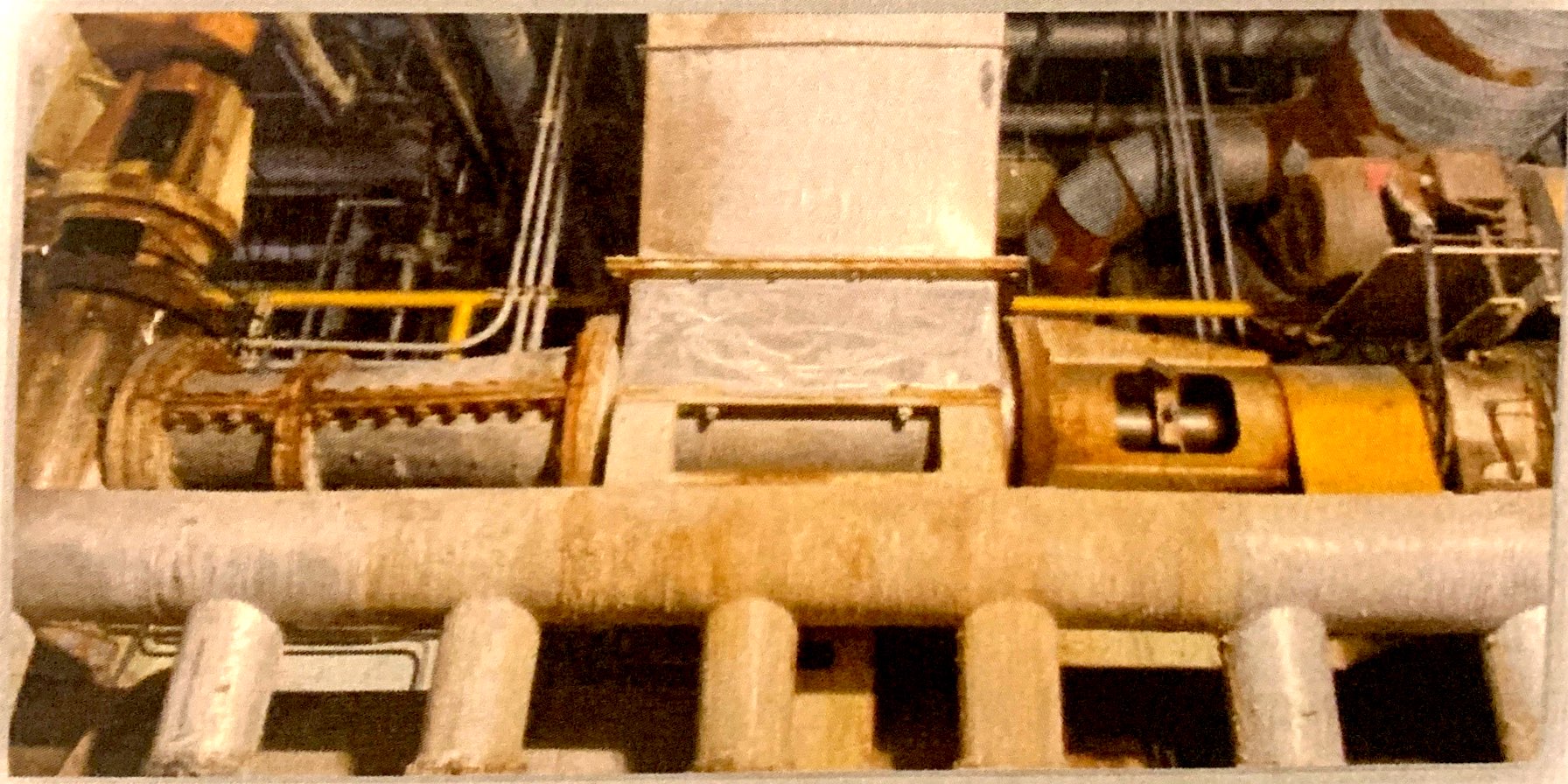

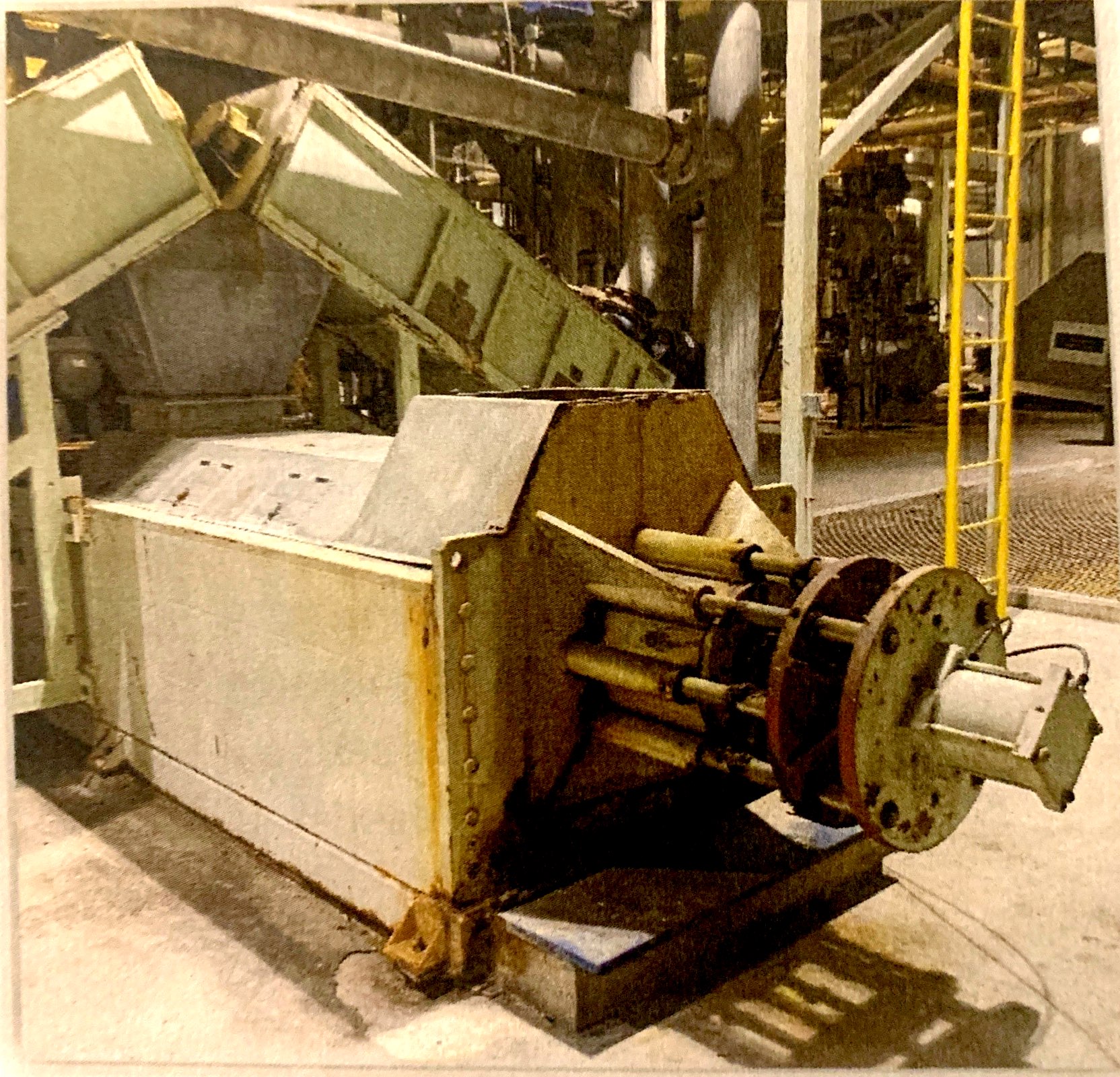

KRIMA SCREW PRESS TYPE RR 550

Features:

- Horizontal Screw Press- pneumatically regulated counter pressure cone (choke) and conical screw core

- Capable of producing and outlet consistency of up to 35% and inlet consistency should be a minimum of 4% based on feedstock

KRIMA PLUG SCREW TYPE 3823

Allows for a closed system and low steam consumption – Used to seal the heating zone

KRIMA SHREDDER TYPE 400

Transforms the pulp plug to from the plug screw into “crumbs” for even heating as it is entered into the preheater stage

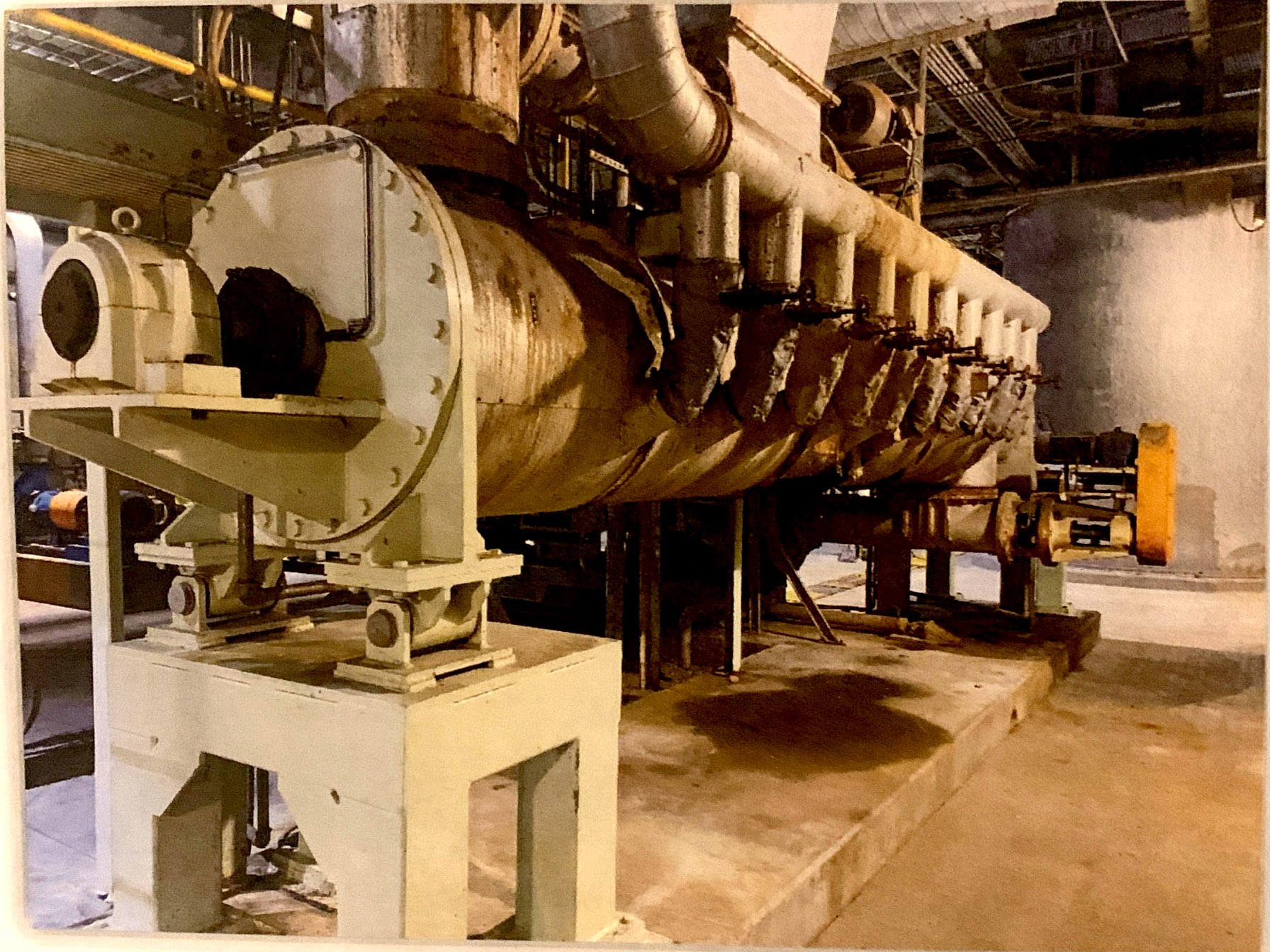

KRIMA PREHEATER TYPE 8050

Auger for preheating pulp through saturated steam to reach desired temperature setpoint. Steam injection ports run the length of this component.

KRIMA INFEEDER TYPE 350

Provides even distribution and consistent feed as pulp enters the disperser

For more info call us (612)810-1955 USA; +52(614)169-3217 Mexico

Krima KD-710 Dispersion System